In marine oil and gas transportation, single-point mooring systems (SPMs) are the core facilities connecting offshore platforms and oil tankers, while underwater oil hoses are an indispensable “energy channel” in this hub. As a key component of SPMs, Zebung Technology’s underwater oil hoses, with their superior performance, provide a solid guarantee for the safe and efficient transportation of marine oil and gas, becoming a “lifeline” safeguarding marine energy transportation.

I. Core Role: The “Flexible Connector” of SPMS

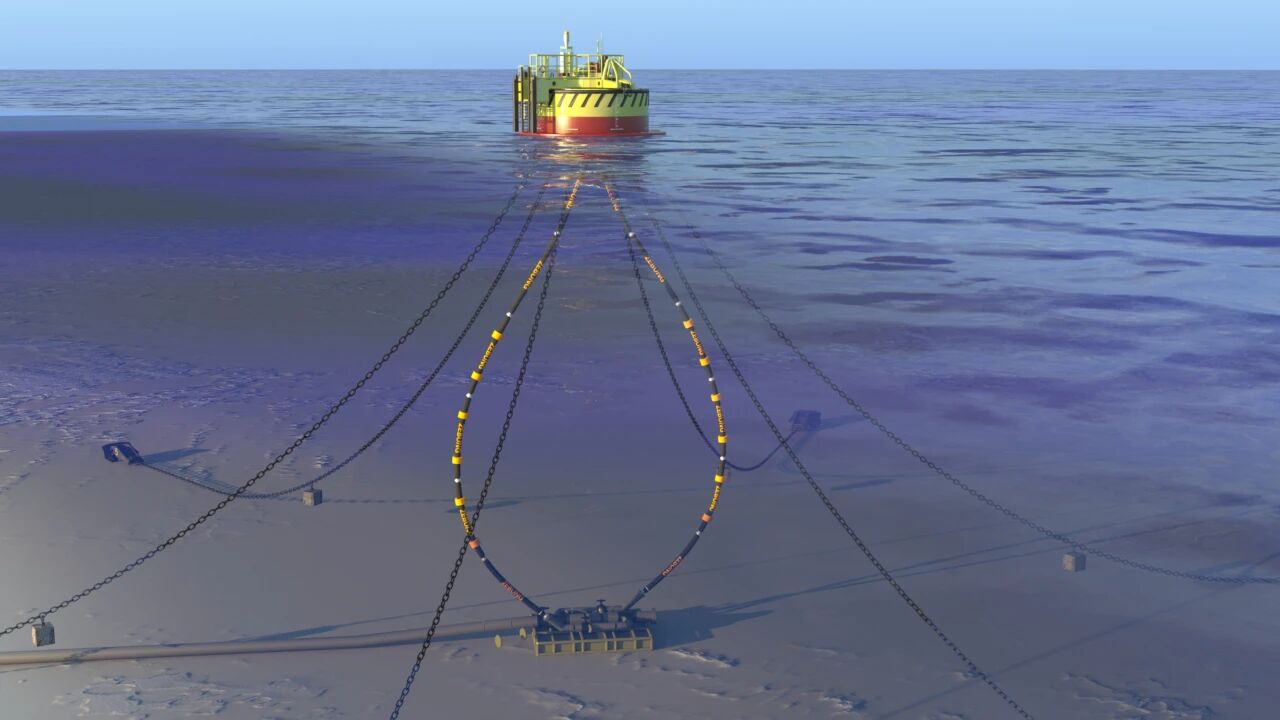

In the turbulent and unpredictable marine environment, SPMs require a stable connection between the buoys and the subsea manifold, and Zebung Technology’s underwater oil hoses are the key carrier for this connection. They shoulder a dual crucial mission:

● Energy Transmission Channel: Directly undertaking the task of transporting the medium, stably delivering crude oil extracted from the subsea manifold to the buoys, and then transferring it to the transport vessel via the buoys. This is the essential route for marine oil and gas from the “seabed” to “land,” ensuring uninterrupted energy transportation.

● Flexible Buffer Bridge: In the marine environment, wind, waves, and ocean currents can cause buoys to sway and shift. Underwater hoses, with their inherent flexibility, can adapt to the relative movement between the buoy and the seabed manifold, offsetting external impacts and avoiding the breakage risk associated with rigid connections. This provides “flexible support” for the stable operation of the entire single-point mooring system.

II. Three Core Advantages: Forging a “Safety Barrier” for Marine Energy Transportation

Zebung Technology understands the importance of underwater hoses for marine oil and gas development. From material selection and manufacturing to testing and maintenance, the entire process is carried out to high standards, giving the product three core advantages:

1. High-Strength Material: A “Robust Armor” Against Harsh Marine Environments

The underwater hoses are made of high-strength specialized materials, easily withstanding pressure at depths of tens or even hundreds of meters. They also possess excellent corrosion and wear resistance—resisting the erosion of seawater salt and marine microorganisms, effectively extending service life and ensuring structural stability in long-term marine environments, preventing damage and leakage.

2. Rigorous Certification and Testing: A Double Guarantee of Operational Reliability

Every Zebung Technology underwater oil hose undergoes multiple rigorous tests and authoritative certifications before leaving the factory, including bending tests, pressure pulse tests, sealing tests, and conductivity tests, eliminating quality issues from the outset. Furthermore, after the hose is put into use, Zebung Technology provides a series of reliable after-sales support services to promptly identify and resolve potential problems, ensuring the hose is always in optimal working condition.

3. Leak Detection Device: The Last Line of Defense Against Risks

To address unforeseen circumstances in marine transportation, Zebung Technology equips its dual-frame underwater oil and gas hoses with dual safety devices:

Real-time monitoring of the internal medium status of the hose. Upon detection of oil or gas leakage, an alarm is immediately triggered, alerting personnel to promptly shut down and inspect the hose, minimizing pollution to the marine environment and threats to production safety.

III. Craftsmanship and Quality, Supporting Safe Marine Energy Development

As the “lifeline” of marine energy transportation, underwater oil hoses play an irreplaceable role in marine energy transport. Zebung Technology is committed to “safeguarding the safety of marine energy transportation”. With its excellent underwater hose products, it provides high-quality and stable services for global marine energy transportation projects, ensuring both efficient and smooth energy transportation and protecting the cleanliness of the marine ecological environment, thus becoming a trustworthy partner in the field of marine energy development.

Post time: Nov-19-2025